Case Studies

The Results Speak for Themselves.

Over the past 14 years, KB Science has supported a myriad of corporations, small and medium enterprise technology companies, hundreds of public and private university clients, nearly all 17 DOE national laboratories, and educational nonprofits to advance technologies that help build a better tomorrow. In the past six years alone, KB Science has helped our clients earn close to $2 billion in federal public-private-partnership dollars, and the number is growing fast. As your unbiased broker, relentlessly focused, we are your essential partner for unstoppable progress.

Our Impact

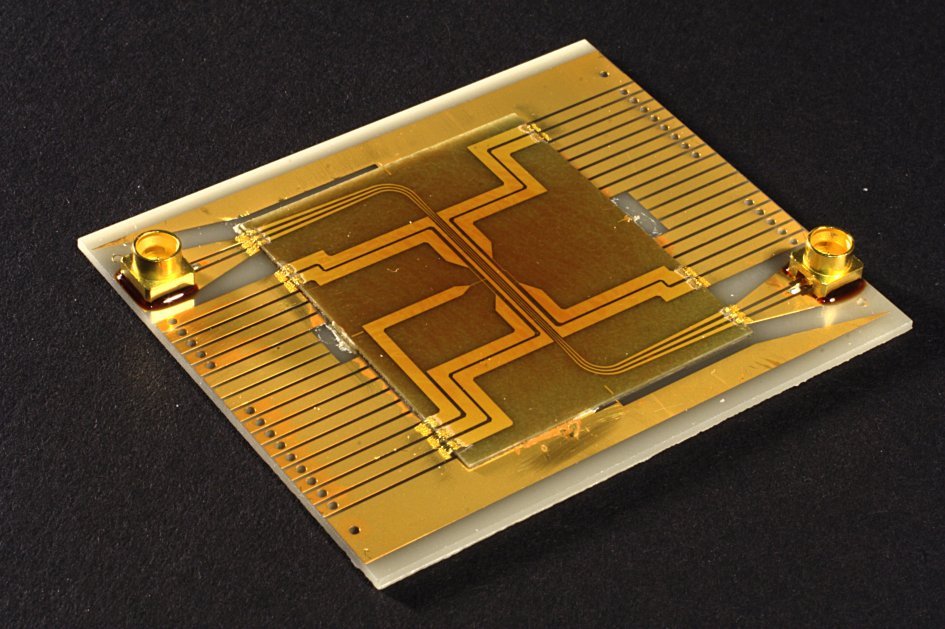

Collaborative Design and Research for the Semiconductor Industry

Micro- and nano-electronic semiconductor “chips” are vital to nearly everything we do, from simple switches to complex smartphones, to automobiles, combat ships, and nuclear reactors. They power all the critical infrastructure that is essential to our quality of life, especially the military systems that ensure our national security. KB Science served as capture managers and the federal proposal writers to secure the five-year grant from the DOC CHIPS R&D Office to establish the SMART USA Institute to advance American digital twin technology and apply it to the semiconductor supply chain to reboot domestic manufacturing and ensure economic and national security. For this project, KB Science guided a team of over 160 participants representing over 90% of the global semiconductor industries, 34 states, DC and Puerto Rico aiming to reduce U.S. chips manufacturing costs by 45%, increase process cycle time 40% and yield 40%, adding 110,000 trained workers in 5 years.

The Result:

● $285 Million from the DOC CHIPS R&D Office and over $680 Million of private investment to establish a state-of-the-art Semiconductor Manufacturing-USA Institute with Digital Twins

"While our team had ample vision, ambition, and hustle, the sheer size, speed, and complexity of the proposal submission process presented an enormous challenge. We would never have reached the summit without the acuity, leadership, and integrity of “KB" and her talented team."

-Todd Younkin, Executive Director of the SMART USA CHIPS Manufacturing Institute.

Demonstrating a Viable Low-Cost Low-Carbon Calcined Clay Cement for U.S Materials Supply

Reducing the cost and increasing the raw materials flexibility of cement, one of the most important global industrial materials, is critical for securing our national supply chain. The U.S. consumes more than 120 million and 30 billion metric tons of cement and concrete a year, and this use is steadily increasing. KB Science served as capture managers to Argos USA (acquired by Summit Materials Inc.) for the winning grant to build four state-of-the-art calcination facilities in Maryland, Georgia, and Texas for American cement and concrete supply. The Department of Energy project will pivot away from the typical limestone-based cement which emits a significant amount of CO2 during the heating process needed to create it. Instead, the new facilities will use the most abundant and cheapest sources of raw materials to demonstrate the a more viable and cost-effective clay-based cement requiring significantly lower temperatures to manufacture. With the help of KB Science as strategists, teaming experts and proposal writers, Summit Materials secured the grant from the U.S. Office of Clean Energy Demonstrations to fund these facilities. These new sites demonstrate the potential for rapid upscaling of this technology, offering a new hope for energy resilience in an industry that desperately needs it.

The Result:

● $215.6 million from the U.S. Office of Clean Energy Demonstrations under the Bipartisan Infrastructure Law’s decarbonization investment program

“KB Science Color Team Reviewers, your participation and support in this process was and is greatly appreciated. Furthermore, your input and coaching were truly helpful in guiding our narrative and perfecting our delivery. Such a great memory for me personally.”

– Christopher Liner, Corporate Strategy & Business Development, Summit Materials

Eliminating Industrial CO2 Emissions from Manufacturing

Heat is essential to manufacturing, but process heating accounts for more than 30% of the nation’s greenhouse gas emissions. By transitioning to clean electricity as an energy source, industries can reduce emissions and improve energy efficiency. KB Science served as capture and proposal managers, providing strategic guidance to a multi-institution team led by Arizona State University, including 37 industries, 9 universities and 3 national laboratories, to secure a five-year grant from the DOE for the new Electrified Processes for Industry without Carbon (EPIXC) Institute. For this project, KB Science helped put together a team with both the technical expertise and the experience to ensure that the transition to a new energy landscape will happen in a truly just manner for the greatest possible equitable benefits to the community.

The Result:

● $70 Million from DOE and $74 Million of private investment to transition from fossil fuels for industrial processes to clean electricity.

“When it comes to large-scale, multi-institution grants from mission agencies, KB Science succeeds in turning the total into more than the sum of its parts. They are masters—the right ingredients to beat the competition, perfectly aligned with the funder’s goals. Kristin and her team are the Michelin Star of winning proposals.”

– Sridhar Seetharaman, PI of the ASU-led Electrified Processes for Industry Without Carbon (EPIXC), US DOE’s seventh Clean Energy Manufacturing Innovation Institute

Innovation for a Cleaner World

Manipulating the intimacies of atomic-level ordering for manufacturing of semiconductors, KB Science supported the University of Arkansas's prestigious proposal development win at the US Department of Energy, in fast action proposal strategy, development, review, and production. The new Energy Frontier Research Center 'µ-ATOMS' will help the nation advance cost-effective transformation manufacturing of microelectronic chips and materials essentials for computers, M-ATOMS, aims to create and develop low-carbon manufacturing processes that will reduce greenhouse-gas emissions.

The Result:

● $10.3 Million for the urgent US need for semiconductor chip manufacturing

“Kristin and KB Science did an amazing job in an extremely tight four-week period to reshape the proposal to be DOE/BES “flavored” and hand-by-hand helped us developing a solid management plan, which laid a winning foundation for our first trial of EFRC competition and placed Arkansas on the EFRC map for the first time! We will definitely come back with full confidence to work with them for our next large competition.”

– Shuiqing (Fisher) Yu

Professor &Director m-ATOMS, University of Akansaa, Fayetteville

Artificial Intelligence and the Future of Robotics

Catalyzing robotics and AI innovative partnerships across the public-private market space, as Capture Manager, KB Science supported Carnegie Mellon University’s Advanced Robotics Manufacturing (ARM) Institute to build the first advanced robotics manufacturing institute for the Department of Defense. Building and managing ARM’s elite membership model of over 300 public and private scientists, technologies, and educators, KB Science led the team and its partners to secure over $160M Institute funding at DOD to establish a future where people and robots work together to respond to our nation’s greatest challenges and to develop and produce the world’s most desired products.

The Result:

● $160 Million towards robotics and AI for our nation's greatest challenges

“Kristin and KB Science are the black belts of the National Network for Manufacturing Innovation. They helped us build the winning foundational synergist core team from deep federal agency know-how and technical rigor. For any large federal public-private innovation accelerator, I would go to KB Science.”

– Howie Choset

ARM Principal Investigator and Chief Technology Officer, Carnegie Mellon

Advancing Nuclear Fusion for Net-Zero

KB Science was the engine behind Cambridge, MA based start-up Commonwealth Fusion Systems DOE ARPA-E grant award, which is helping them catapult their leadership in low-cost commercial fusion through high-temperature superconducting magnet technologies. Confining spinning plasma at 150 million degrees Celsius, the new magnetic technology designs are helping the company demonstrate magnetic confinement in unprecendented ways. Shortly after the federal award, CFS raised over $1B in private venture funds paving the way to low-cost commercial nuclear fusion by 2025, and realizing fusion power plants by 2030. The aim, a truly carbon-free world.

The Result:

● $3.6 million from DOE APRA-E to advance nuclear fusion

“KB Science is the go-to firm for DOE. They will teach all every detail to do it. They will teach you how to win.”

– Michael Segal

CFS Chief Innovation Officer

Clients Who Win With Us

Universities

Arizona State University

Carnegie Mellon University

Georgia Tech

Massachusetts Institute of Technology

Michigan State University

Penn State University

University of Delaware

University of Michigan

University of Nebraska-Lincoln

University of New Hampshire

University of Pittsburgh

University of Utah

Laboratories

Ames Laboratory

Argonne National Laboratory

Fermi National Laboratory

Idaho National Laboratory

Jet Propolsion Laboratory

Lawrence Berkeley National Laboratory

National Renewable Energy Laboratory

Sandia National Laboratories

Thomas Jefferson National Accelerator Facility Lab

Oak Ridge National Laboratory

Businesses & Non-Profits

American Institute of Chemical Engineers

American Iron and Steel Workers

Commonwealth Fusion Systems

Chemours Company

DEKA, Inc

Electric Hydrogen

Mentis Sciences

Pixelligent

polySpectra

Stanford Research International Inc.

TC Energy

VIA